Reducer, as an important transmission device widely used in various mechanical equipment, has the function of reducing speed and increasing torque.In order to meet the needs of different application scenarios, the classification of reducer models is also quite rich.This article will elaborate on the classification of reducer models and their characteristics.

What are the reducer models?

1. Reducer model classification

Classification according to transmission type

Gear reducer: This is the most common type of reducer, which transmits power and reduces rotational speed through the meshing of gears.This reducer model has compact structure and high transmission efficiency.

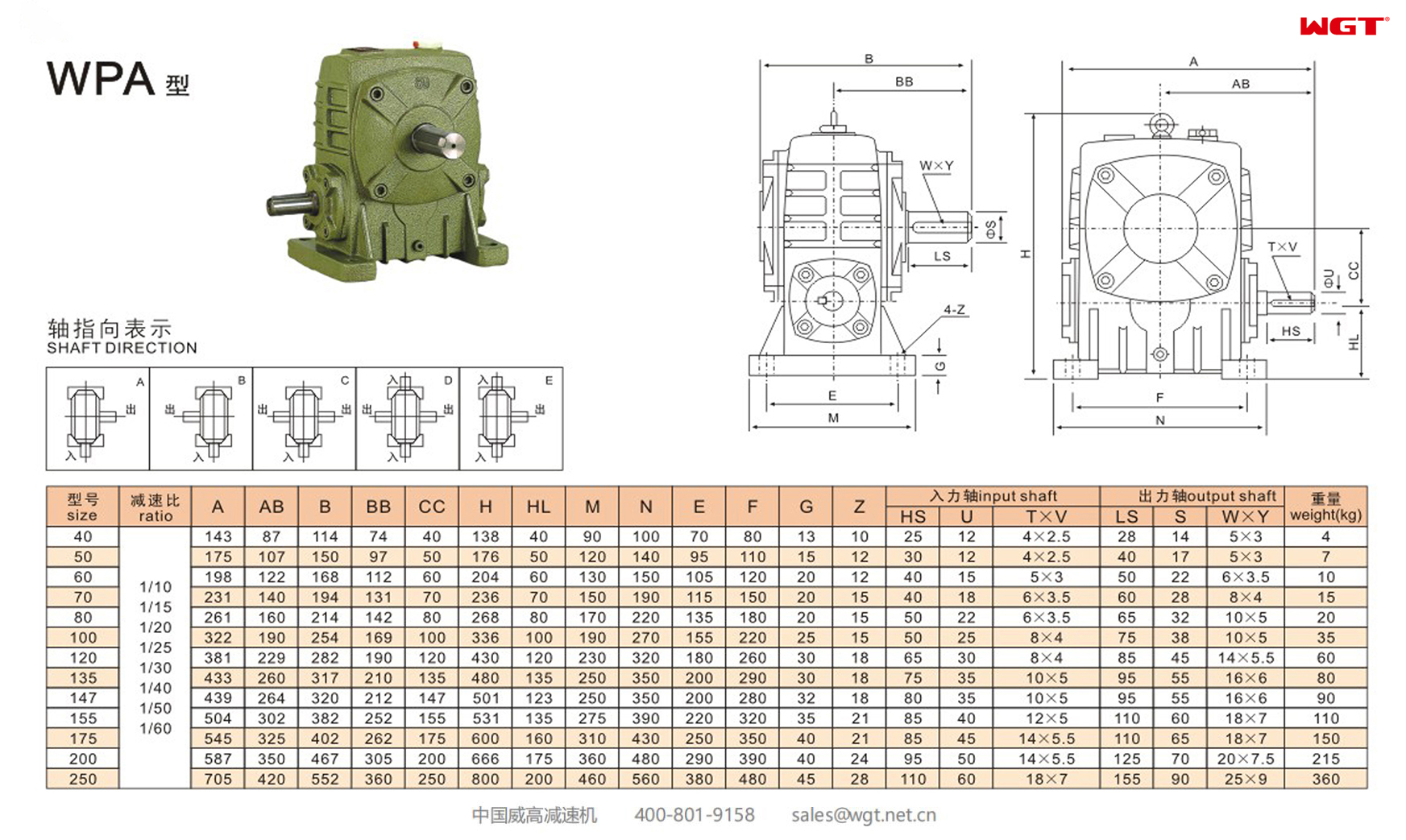

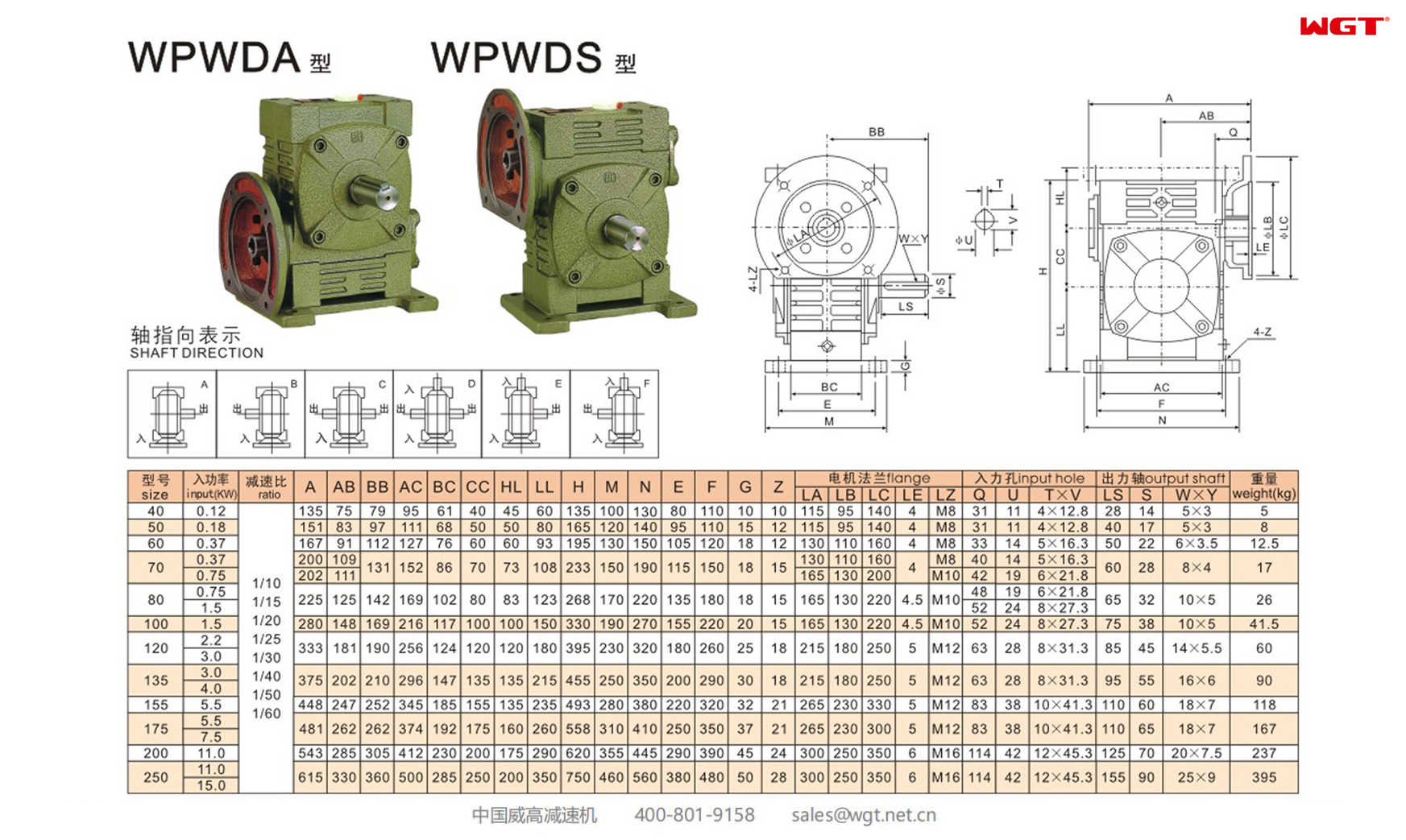

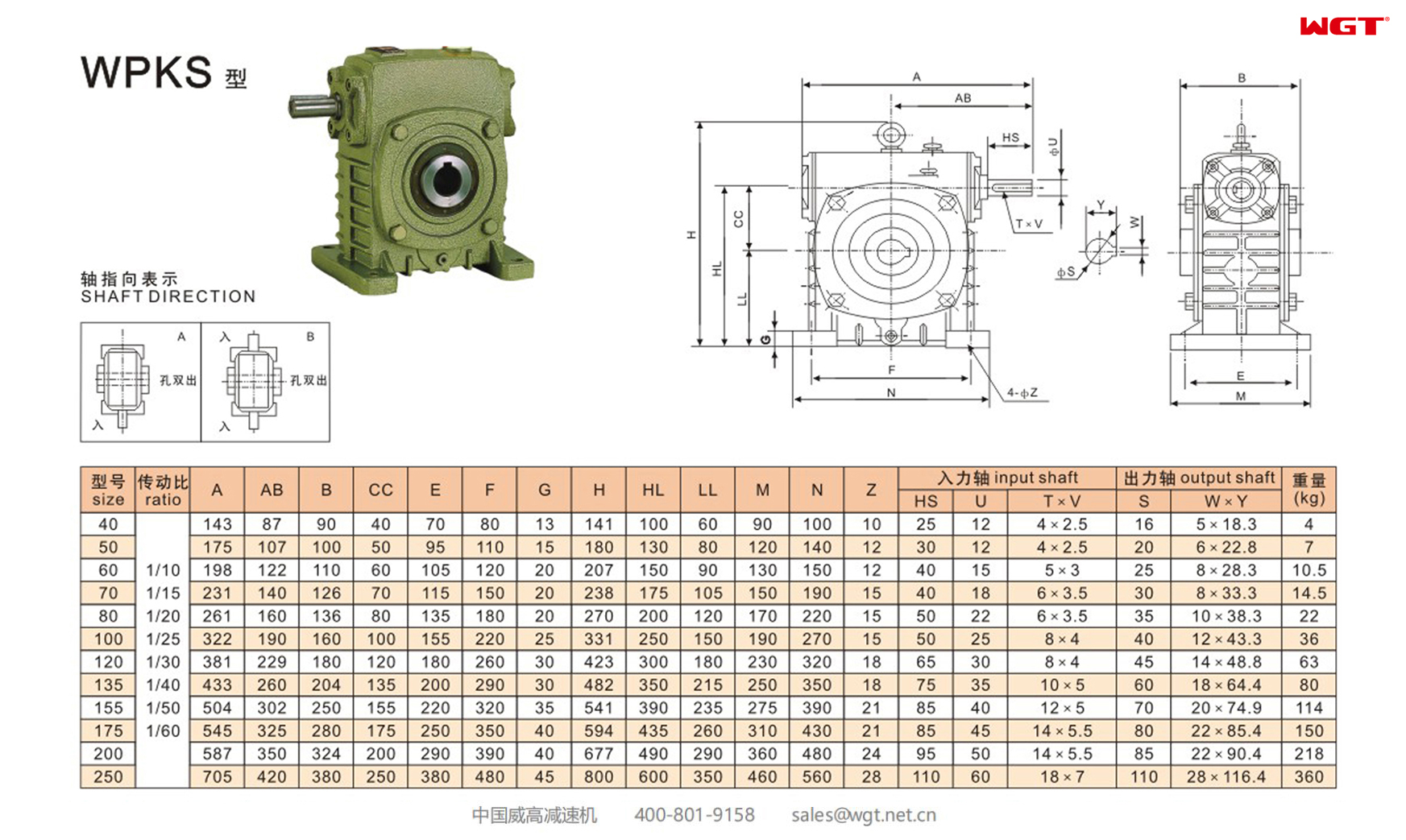

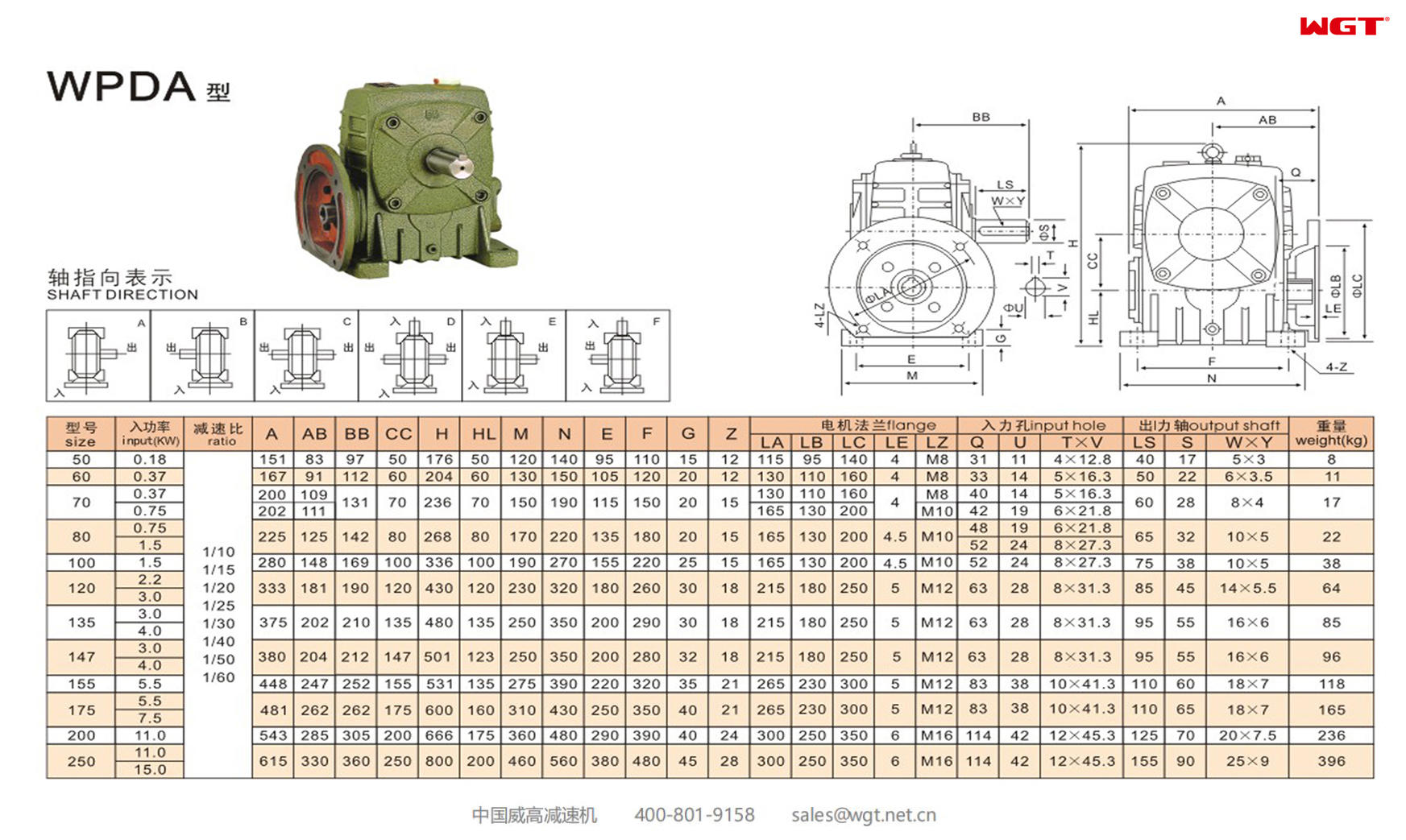

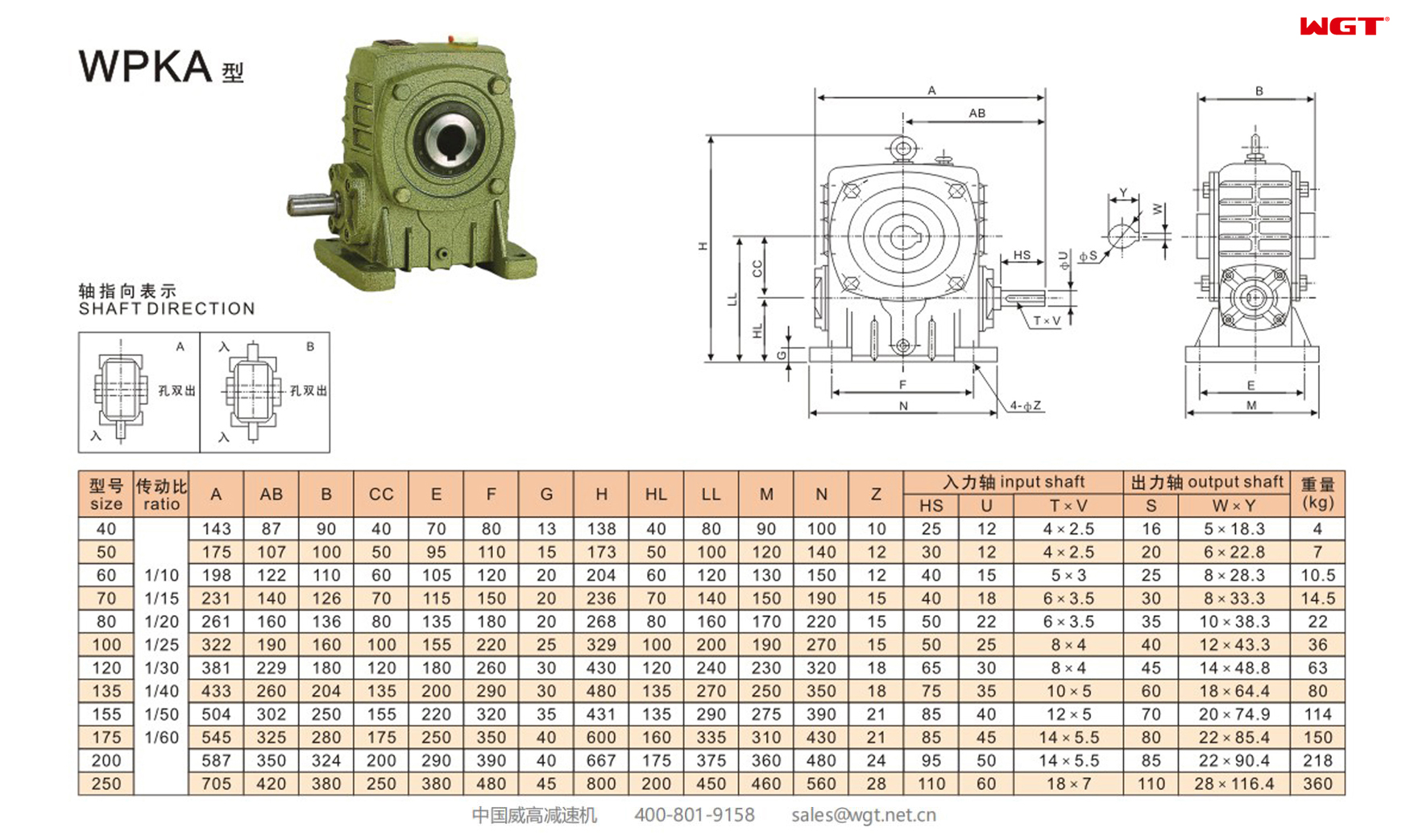

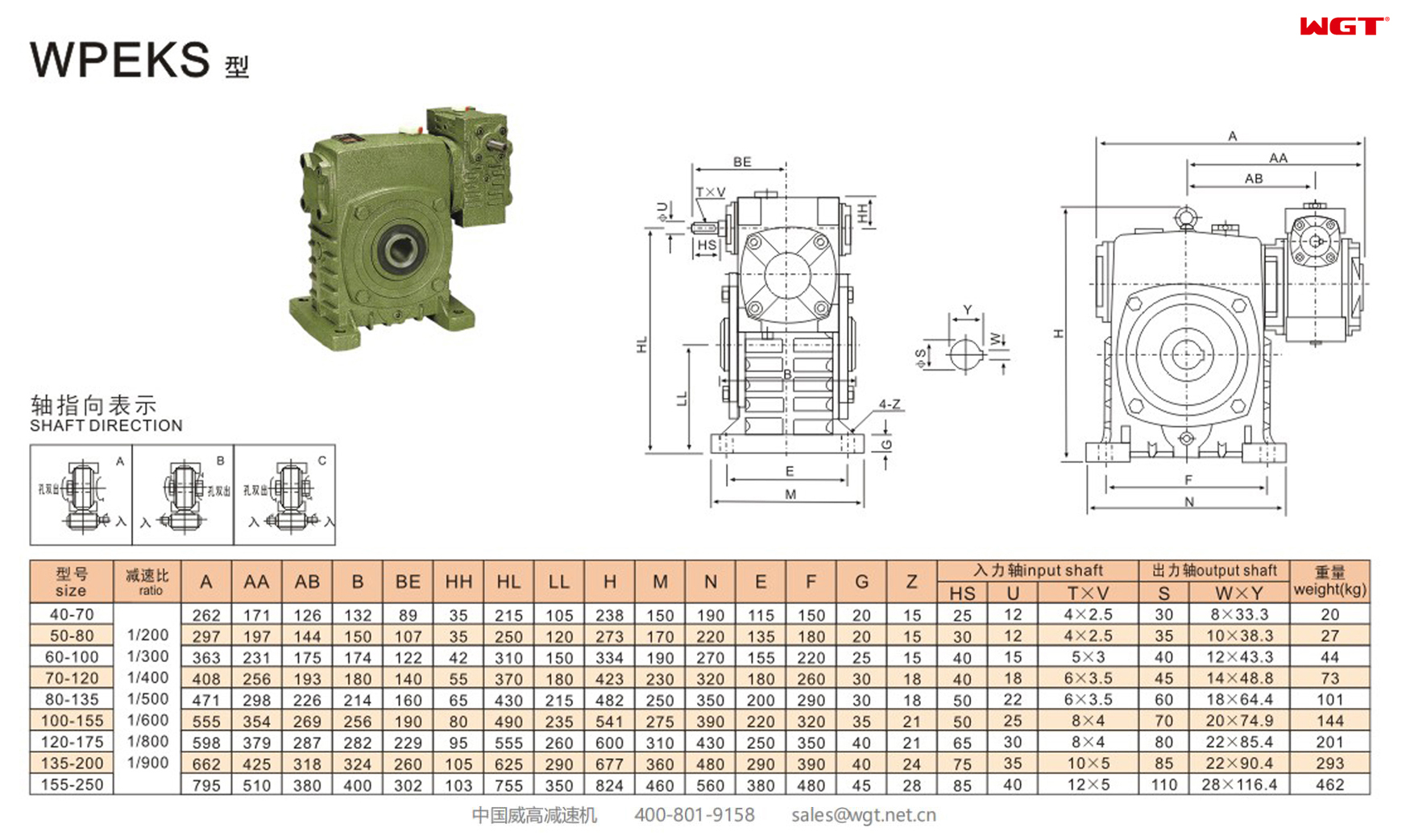

Worm gear reducer: uses the rolling friction between the worm gear and the worm to achieve deceleration.It is characterized by simple structure, small size, but relatively low transmission efficiency.

Classification according to installation method

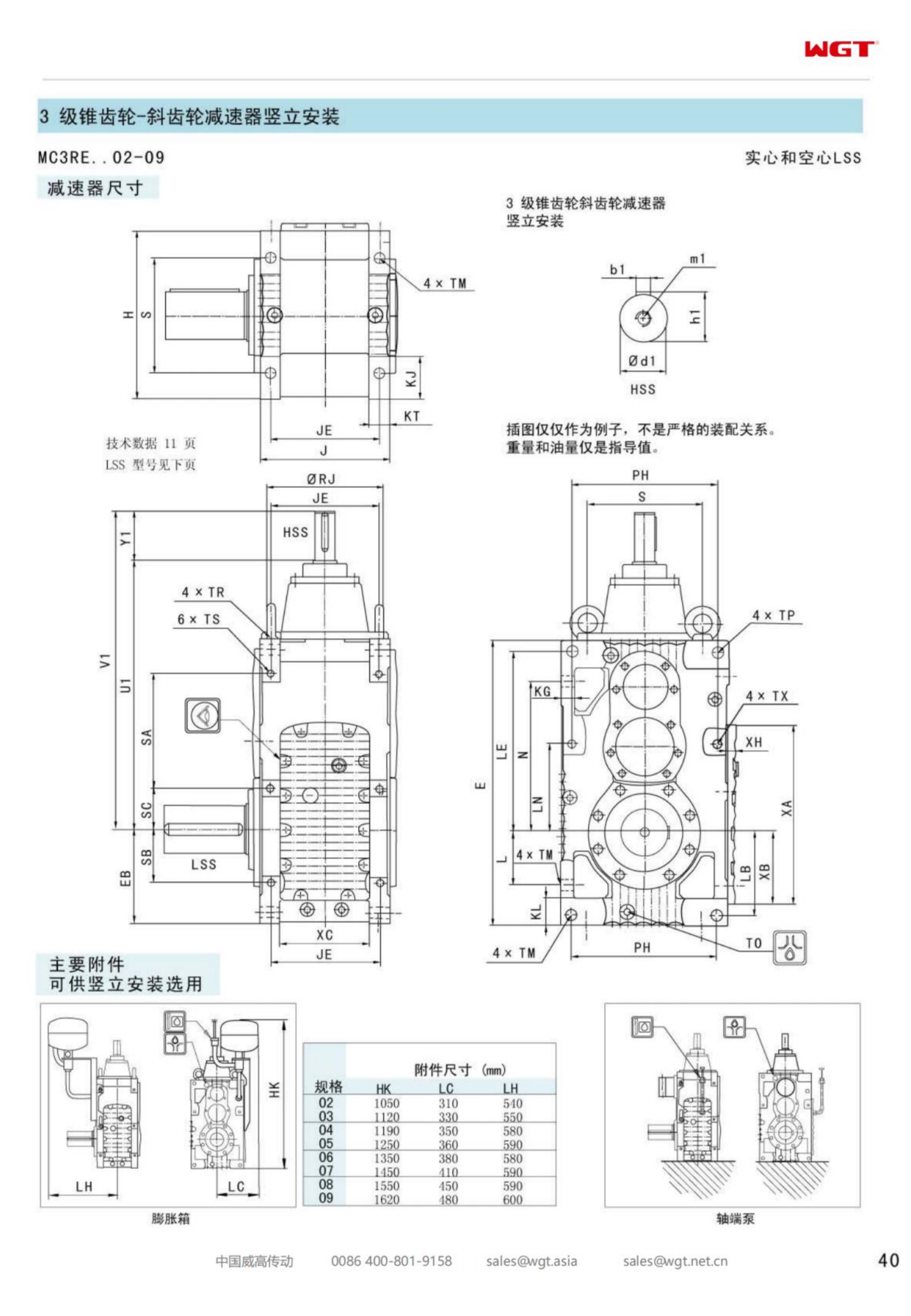

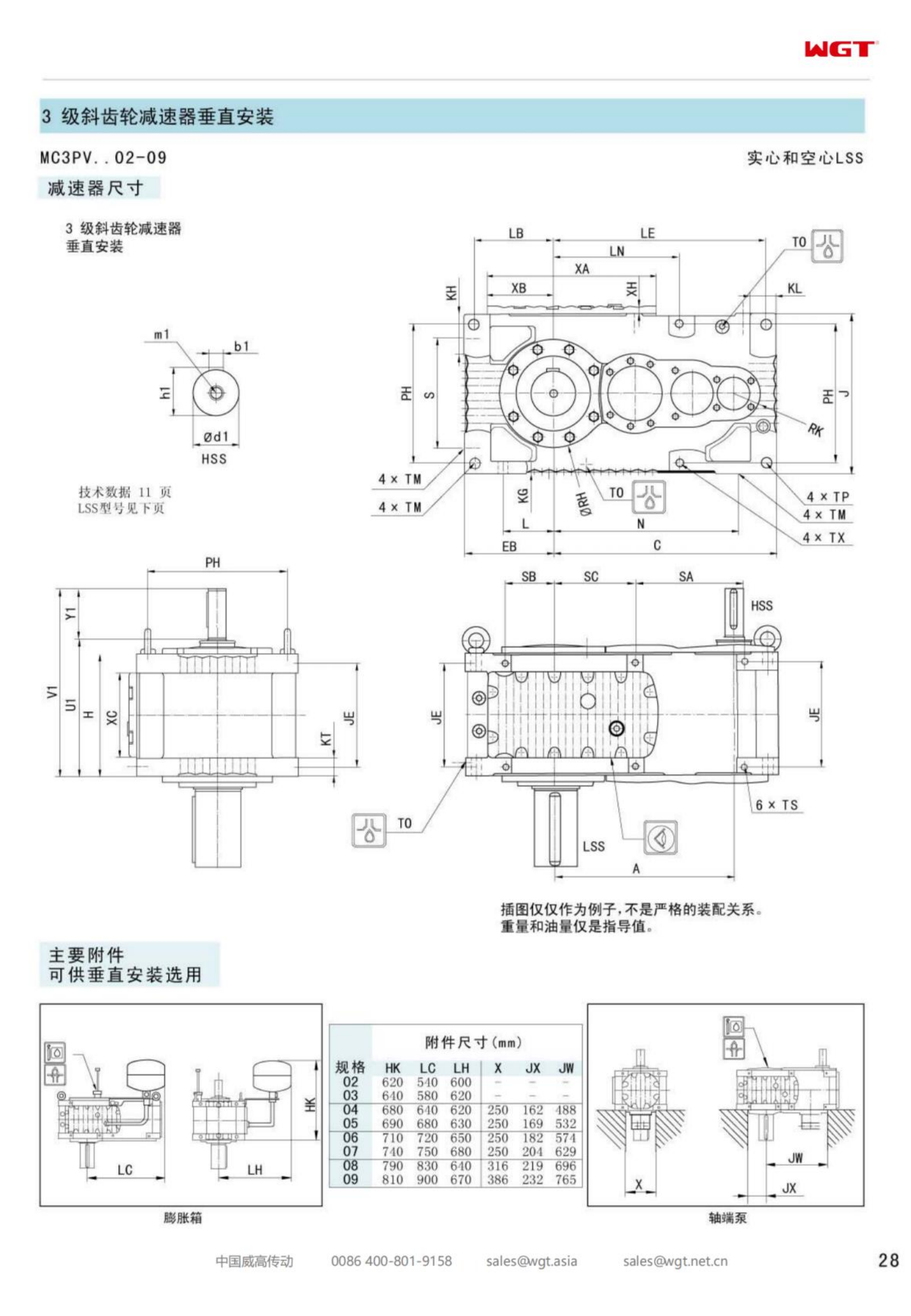

Vertical reducer: This type of reducer model is usually designed to be installed vertically, takes up little space, and is suitable for occasions where space needs to be saved.

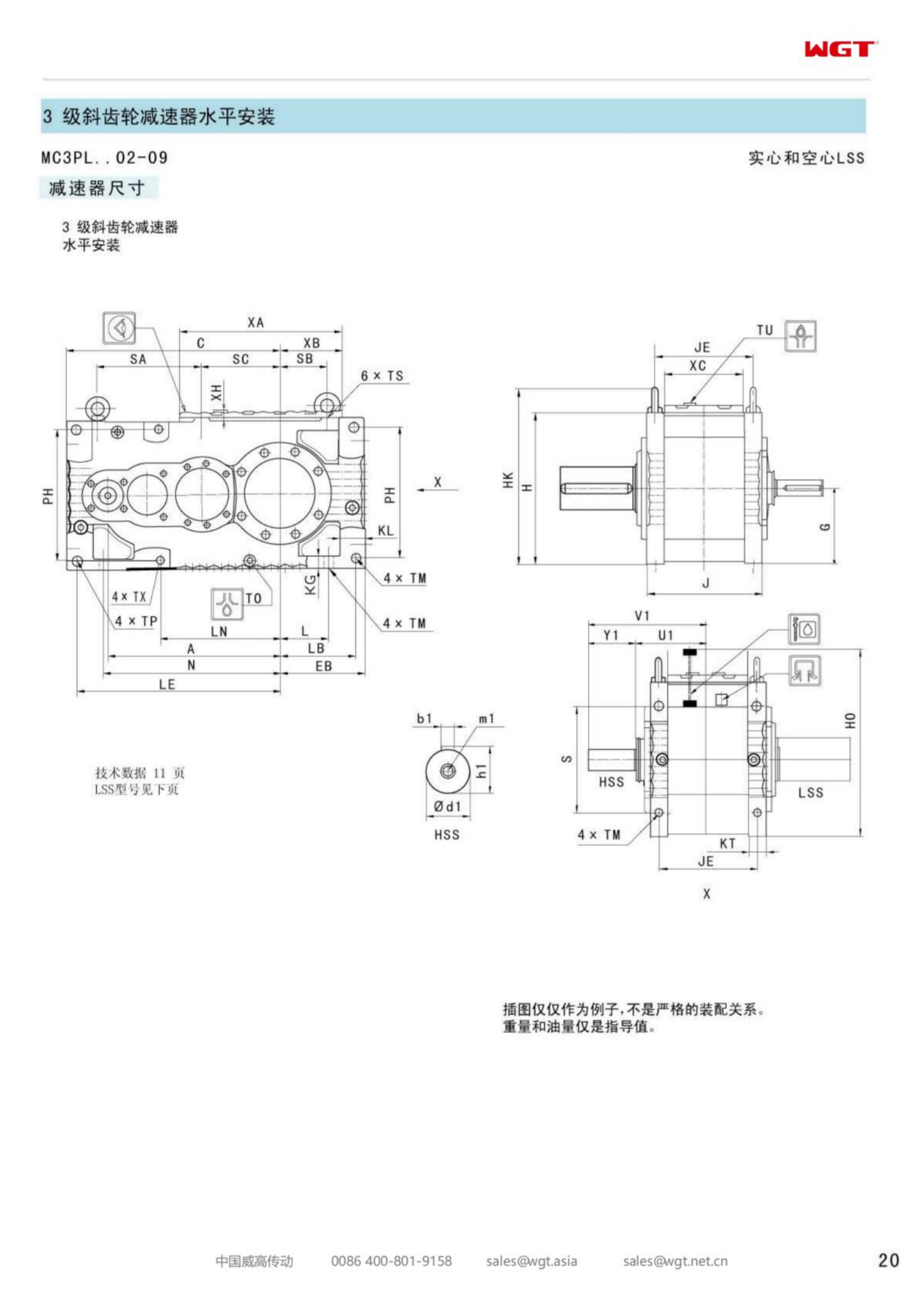

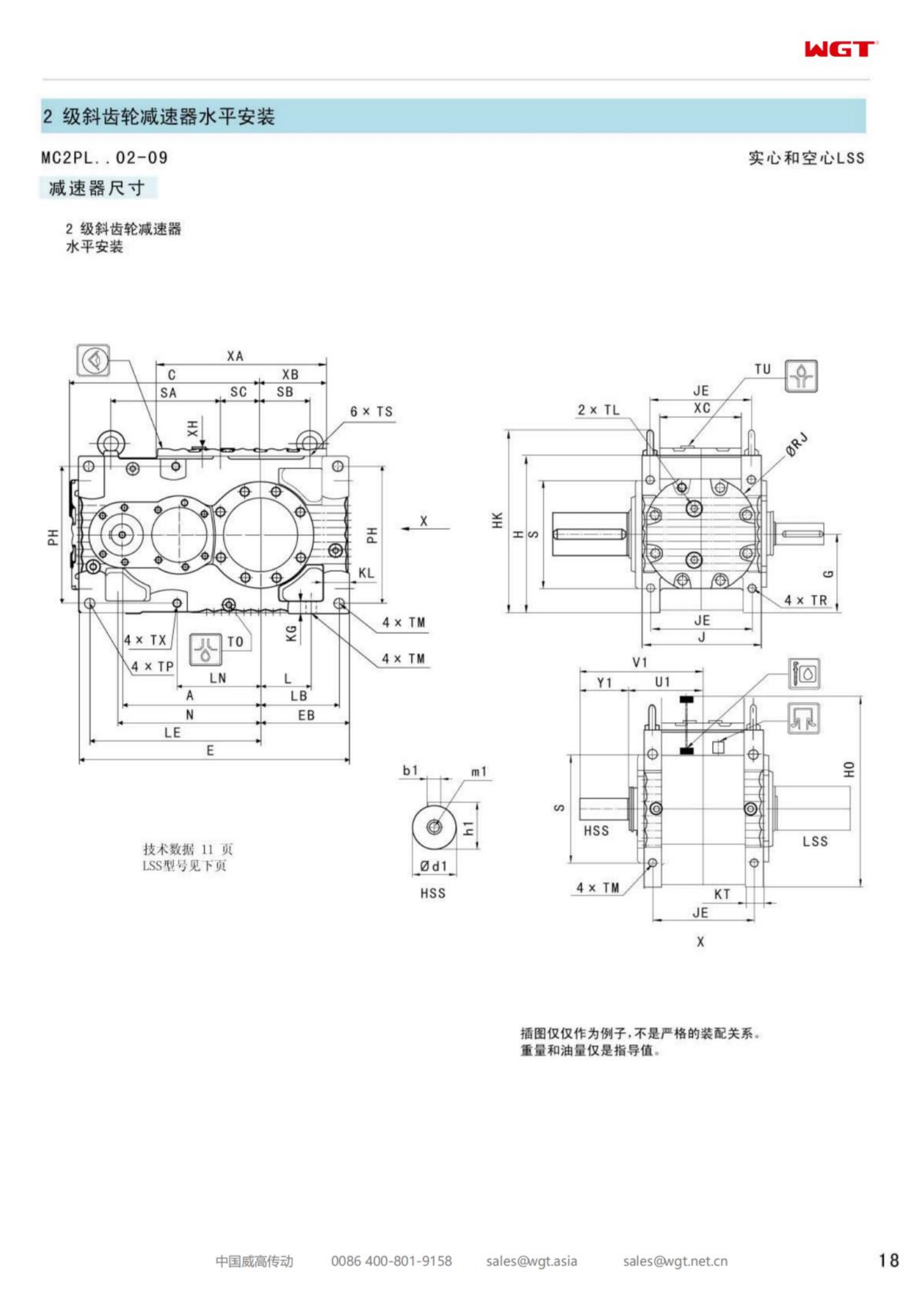

Horizontal reducer: A horizontally installed reducer model with stable structure and suitable for large mechanical equipment.

Classified by output method

Solid shaft output reducer: The output shaft is a solid shaft, directly connected to the working machinery, and has high structural strength.

Hollow shaft output reducer: The output shaft is a hollow shaft, which can transmit power through the shaft center or install other components, and the design is flexible.

Classified according to usage occasions

Special reducer: a reducer model designed for specific mechanical equipment, such as special reducers for metallurgy, mining, etc.

Universal reducer: A universal reducer model suitable for various occasions and has wide applicability.

2. Features of reducer models

Diversity: There are many types of reducer models, and the appropriate model can be selected according to different needs and application scenarios.

Efficiency: Modern reducer design focuses on improving transmission efficiency and reducing energy loss.

Compactness: With the development of technology, the structure of reducers is becoming more and more compact, occupying a small area.

High precision: High-precision reducer models can ensure the stability and accuracy of transmission.

High reliability: High-quality reducer models have the characteristics of long life and low failure rate, which can ensure the long-term stable operation of mechanical equipment.

Easy maintenance: Modern reducer design focuses on ease of maintenance, making it convenient for users to perform daily maintenance and upkeep.

Modular design: Many reducer models adopt a modular design, allowing users to customize and expand according to their needs.

Wide adaptability: Different models of reducers can adapt to different working environments and working conditions, such as high temperature, low temperature, humidity and other environments.

Environmental protection: Modern reducers pay attention to the concept of environmental protection in the design and manufacturing process, and use environmentally friendly materials and processes to reduce the impact on the environment.

Intelligent trend: With the development of Industry 4.0 and intelligent manufacturing, more and more reducer models integrate sensors and intelligent control modules to achieve remote monitoring and intelligent management.

To sum up, the diversity and characteristics of 'reducer models' enable them to be widely used in various mechanical equipment to meet different transmission needs.When selecting and using reducer models, actual application scenarios and needs should be fully considered to ensure that the appropriate reducer model is selected and implemented